Package

Adiabatic Dry Cooler

MAXIMUM EFFICIENCY IN ALL AMBIENT CONDITIONS

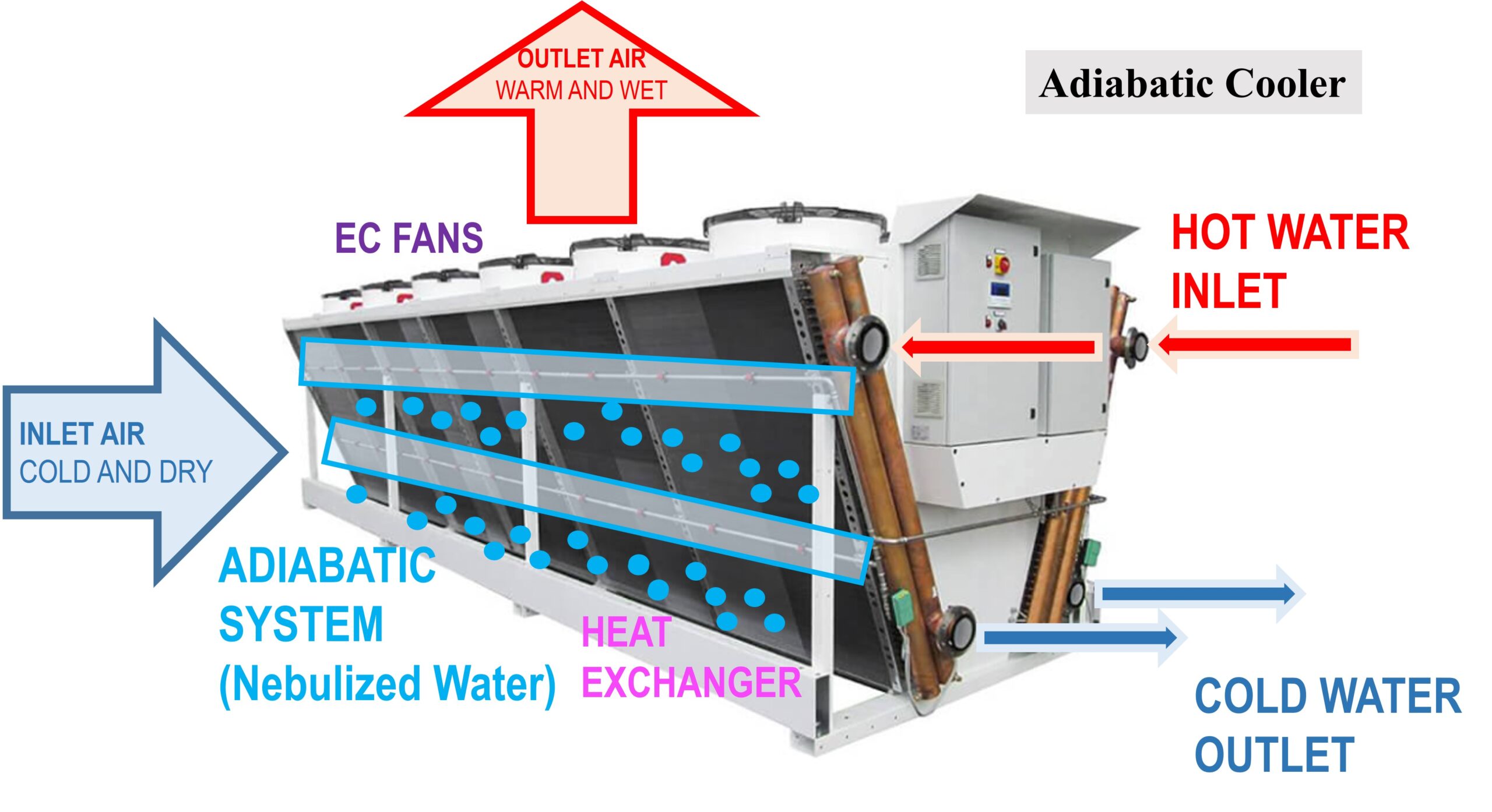

Adiabatic dry cooler are advanced cooling systems that combine the principle of dry cooling with an adiabatic system to enhance efficiency during periods of high temperatures. This technology is particularly suitable for industrial applications, data centers, and air conditioning systems, as it optimizes cooling while reducing water consumption compared to traditional evaporative towers.

ILMED IMPIANTI’s Adiabatic Dry Coolers obtain an higher efficiency using adiabatic cooling. The process is as follows:

- Adiabatic Cooling: fresh air passes through a wet evaporative panel. Water evaporates absorbing heat from the air and lowering the temperature.

- Heat Exchange: The cooled cooling air flows through the cooler tubes, exchanging heat with the hot fluid.

- Fluid Cooling: The hot fluid cools, allowing the process or application for which it is intended to be effectively cooled.

- Optimized Efficiency: This approach improves efficiency, especially in hot climates, and reduces working costs.

Applications:

- Cooling of industrial processes.

- Air conditioning in commercial buildings.

- Cooling of servers in data centers.

- Customized applications based on customer needs.

Heat exchange batteries:

- All the finned coils of the liquid coolers are made with copper tubes and aluminum fins with high efficiency pyramidal corrugation

- The battery frame is made of FeZn of a thickness suitable for the weight of the exchanger

- To eliminate tube breakage problems, all the expanding is carried out on aluminum backings so that there is no direct contact between the copper tubes and the iron frame

Casing:

- The liquid coolers are made with FeZn casing painted with RAL9016 epoxy powder

- The fan nozzles are of the high collar type made to obtain maximum performance and minimum noise

Electric fans:

- All standard motors are 400V – 3F – 50Hz

- 60 Hz versions are available on request for all diameters

- The motors are of the external rotor type with IP54 protection and very high efficiency

- Statically and dynamically balanced fans

Final Testing:

- All coils are tested with dry air and adequately degreased

- For the standard versions the maximum operating pressure is 10 bar