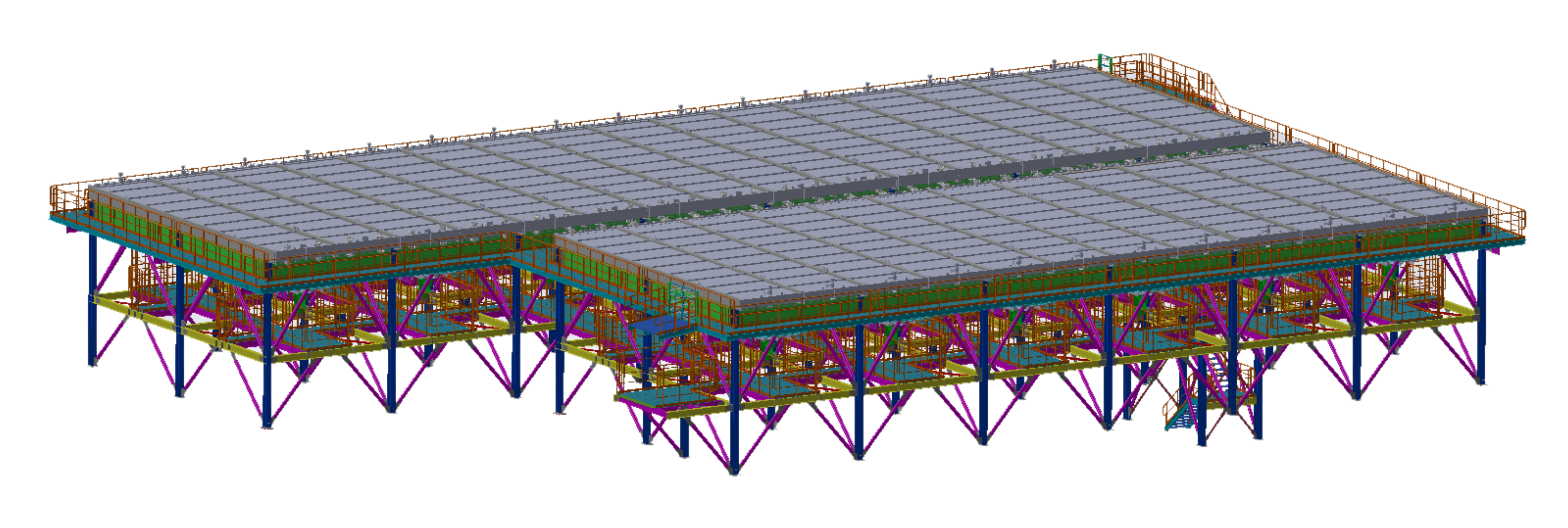

Field Erected

Air Cooler

AIR COOLERS

Air Coolers, or air-cooled heat exchangers, are devices designed to dissipate heat from a fluid (water or water mixed with ethylene or propylene glycol) by using the airflow generated by fan units composed of fans, electric motors, and transmissions. The hot fluid flows inside finned coils, while the air drawn from the environment passes over the heat exchange surfaces, enabling cooling through forced convection.

Compared to evaporative cooling towers, Air Coolers provide dry cooling, avoiding water consumption and reducing operating and maintenance costs.

Technical Features

ILMED IMPIANTI Air Coolers are designed to ensure maximum efficiency, reliabili-ty, and long-term durability. The main features include:

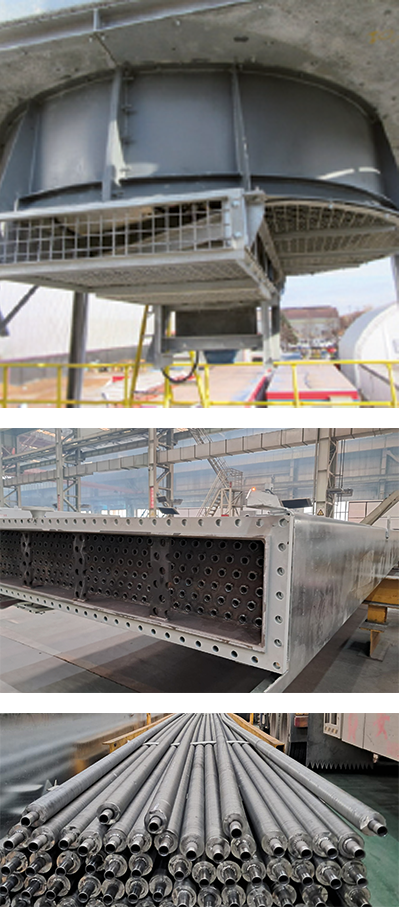

- Heat exchange coils: composed by finned tubes available in various diameters (25.4 mm, 31.8 mm, and 38.1 mm) and materials (carbon steel, stainless steel, special alloys) to withstand high temperatures and aggressive environments.

The aluminum finning (G-fin, L-fin, or Extruded) is designed according to project conditions and customer requirements.

The headers of the tube bundles can be manufactured in various types (welded, with removable cover, removable bonnet, or with plugs) based on maintenance and internal inspection needs. - Flexible configuration: available in different configurations: forced draft or induced draft, with coils arranged horizontally, vertically, or in inclined frame (A-frame or V-frame) to optimize space and cooling efficiency.

- High-performance fans: axial type, with speed control capability (using motors powered by inverters) to adapt to process needs. The fans are designed based on the sound emission levels required by the project, even for low or ultra-low noise applications.

Applications

Air Coolers are used in various industrial sectors, including:

- Power generation: used in cooling systems for turbines, generators, and condensers.

- Food and pharmaceutical industry: used in production processes that require efficient cooling without contamination.

- Steel and metallurgical plants: for cooling high-temperature fluids in metal processing operations.

Features and Advantages of Air Coolers

- Water Savings and Environmental Efficiency

– Zero water consumption: Air Coolers cool the fluid using air only, eliminating water use and the associated treatment and disposal costs. – No humid air emissions: unlike evaporative cooling towers, they do not release saturated air that has been in contact with process water, reducing the risk of contamination and corrosion around the plant.

– No visible plume: ideal for urban areas or locations with environmental constraints. Reduced Operating Costs – Lower operating expenses: no need for water supply, filtration, or treatment. – Low energy consumption: modern high-efficiency fans with speed control optimize energy use and lower energy costs. - Greater Reliability and Durability

– Weather resistance: made with corrosion-resistant materials, ensuring long service life even in harsh environments or with aggressive water.

– No risk of freezing: when equipped with anti-freeze configurations (e.g., louvers and/or steam coils), Air Coolers are ideal for extremely cold climates, with no danger of pipe freezing. - Flexibility and Customization

– Wide range of configurations: designed to adapt to space constraints, energy consump-tion requirements, and noise limitations.

– Advanced control system: can be integrated with industrial automation systems for continuous performance monitoring. - Safety and Regulatory Compliance

– No contamination risk: the closed-loop system prevents contact between the fluid and the external environment, ensuring higher safety in industrial processes.

– Environmental compliance: the absence of water discharge and efficient energy use allow compliance with the most stringent environmental regulations.